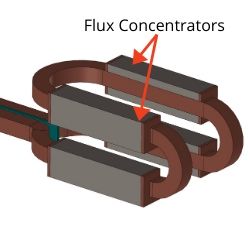

Flux Concentrators are devices added to inductors that alter the magnetic field and direct or intensify the magnetic flux in a specific direction resulting in a more efficient inductor design. By definition, a magnetic flux concentrator is a piece of ferrous material, such as steel, that is used to direct or intensify magnetic flux towards a surface. They are ideal for manipulating the field due to their magnetic properties. eldec uses two different types of flux concentrators based on the application.

The first type of concentrator is called a lamination or lam. Lams are thin sheets of electrical steel, which are stacked tightly together on edge to form a stiff structure with high mechanical strength that is ideal for clamping inductor coils in place. They are coated to increase the electrical resistance from one to the next. eldec stocks laminations in standard U-shapes based on various tubing sizes typically used for induction coils. Laminations cannot be used on high frequency applications (above 50kHz) as the high frequency induction field will directly heat these thin steel sheets.

The second type of concentrator is a soft magnetic composite material known as ferrotron. Ferrotron contains powdered ferromagnetic materials and a dielectric bond compressed properly under high pressure. It is easily machined into unique and complex shapes. While ferrotron is technically soft in the magnetic field sense, it is also not recommended for clamping on with a heavy mechanical load. In those cases, you may consider a G-10 backer plate. Ferrotron can be used in both medium and high frequency applications up to approximately 500kHz.

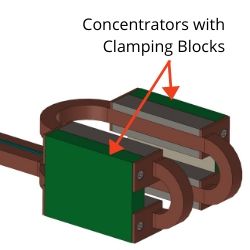

What are clamping blocks?

Clamp blocks are rigid blocks that can be attached to an induction coil for use in clamping the inductor. These blocks are made of non-conductive material (typically made out of G10) to keep them from inductively heating and to enable usage of metal clamps without shorting out the inductor. The clamp block also spreads the clamping pressure across a wider area of the inductor.

Clamp blocks are rigid blocks that can be attached to an induction coil for use in clamping the inductor. These blocks are made of non-conductive material (typically made out of G10) to keep them from inductively heating and to enable usage of metal clamps without shorting out the inductor. The clamp block also spreads the clamping pressure across a wider area of the inductor.

If you have questions whether flux concentrators or clamping blocks are needed for your next coil, please contact us. We'd be happy to discuss your specific workpiece and application.