eldec's edge -- creating the perfect recipe of geometry, frequency, power and magnetic field properties.

The induction recipe is critical in maintaining accurate and steady temperatures that provide more precise heating results. Our highly skilled technicians with extensive experience and expertise in induction heating coil design are our advantage. Before starting induction heating coil fabrication our staff will review part drawings and sample parts as well as your current process. They will then suggest adjustments to production to improve the precision of the inductor and efficiency of your operation.

Table of Contents:

- Design and build custom inductor to reach maximum production potential

- The important induction coil design parameters

- The process of designing custom induction coils

- Inductor fabrication options

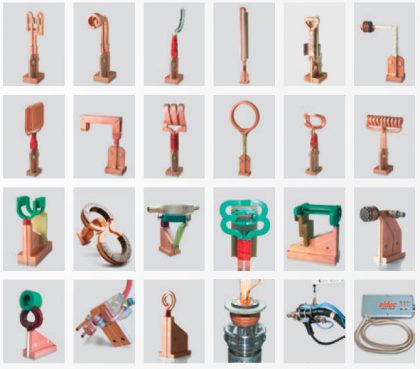

- Custom inductors designed for a wide variety of processes and applications

- All shapes, sizes and brands coil replacement

Design and build custom inductors for maximum production potential

Plotting out the process as well as creating a custom inductor coil design can have a huge impact on overall manufacturing efficiency, part quality and the cost of manufacturing. Time and energy saved to reduce labor and utility costs and to create better parts mean less rework and happier, loyal returning customers. Years of experience in custom building induction coils and developing process blueprints means you won’t have to reinvent the wheel. Our technicians know what works and we can put our expertise to work for you.

The important induction coil design parameters

Physical parameters that determine an induction coil’s design often include:

- Space constraints around the object to be heated will impact tubing size, types and shapes of concentrators used as well as the coil configuration. For example, knowing whether or not the part can be accessed from multiple directions would affect the coil’s design.

- Dimensions of the part or joint to be heated will influence the design. Are there any heat sinks that need to be considered?

- What type of material are you heating? Copper, steel, stainless steel or aluminum?

- Which process will be used? Will you braze, shrink-fit, anneal or harden?

- If you are brazing, what type and shape of alloy will you use? Will the alloy be cut-to-fit thin sheets or fed during the braze?

- What is the target temperature and does the part need to be held at a certain temperature for any specified length of time?

The process of designing custom induction coils

Discussing the specific details of the customer’s part and process mark the beginning of the inductor design process at eldec. We will:

- Review part drawings and sample parts to determine output power requirements. The mass of the material being heated and any potential heat sinks that exist are directly proportional to the power required. Drawings also provide our engineering team with the information required to design the inductor and determine the space constraints that may exist around the part heated. eldec often uses sample parts for preliminary tests to determine actual power requirements rather than relying on experience and calculations alone. In addition, we may use a short video of a preliminary trial with an inductor we already have on hand to demonstrate the proposed process to the customer’s managing staff.

- Use the latest 3D CAD software for inductor design. eldec uses SolidWorks to design all inductors in 3D. Using a customer’s sample work part or drawing and the surrounding clearances as a 3D model, our engineering team can add eldec inductors right into the model to troubleshoot any interference issues that may come up.

- Physically test the final coil design on the real part. Having real parts on hand early on helps us to determine output power. It can also be beneficial for our engineering team to see the physical part as they design the inductor. In addition, when ordering an induction system, physical parts enable our team to begin defining and developing the heating process before a machine is packed for shipment.

- Development of a recipe (power and time settings) for the final production process. Process development typically takes place after an induction power supply order is placed and the machine is built. A recipe is generated on the customer’s actual machine using their custom-built inductor. In addition, process development can also be ordered as a preliminary step through the placement of a Process Development order. This type of process development typically includes the design, build, and modification of inductors and tooling in a mock-up type configuration. These tools can then typically be upgraded to production ready versions after an equipment order is placed.

Inductor fabrication options

eldec offers several options for induction coils. They can be used separately or in combination to intensify magnetic flux, secure a workpiece or to protect your coil investment.

- Flux concentrators – devices added to inductors that alter the magnetic field and direct or intensify the magnetic flux in a specific direction resulting in a more efficient inductor design.

- Clamping blocks – rigid blocks that can be attached to an induction coil for use in clamping the inductor.

- Coax Saver – an adapter that acts as a short extension between the coax transformer and the induction coil that can prevent costly damage to a coil.

- Swivel joints -- a special connection in the coil leads that enables the operators to put an angle in the leads.

Custom inductors designed for a wide variety of processes and applications

Typically, an inductor’s uniqueness is determined by the part’s geometry and accessibility as well as the location that requires heat rather than by the process being performed. Additionally, an induction coil's shape impacts the creation of the magnetic field. For example, surround or OD heating coils (a coil placed on the outside of the part) are inherently more efficient than ID heating coils that are placed into the bore since the current in the inductor wants to travel the shortest distance, which is to the inside edge of the turn. If the part is on the outside of that turn, the current will not be as strong on that part of the inductor, which makes the inductor less efficient. Nevertheless, flux concentrators (laminations and ferrotron) are very helpful in redirecting and concentrating the magnetic field to increase efficiencies of an ID coil if accessibility rules out using an OD coil.

That said, certain types of coils are more likely to be used for specific processes in order to increase the inductor's efficiency and precision. The following examples offer a few suggestions of possible uses.

Induction heating coil design for induction brazing –

A face heating inductor is typically used for brazing squirrel cage rotors for electric motors. In this case, the rotor is placed on top of the inductor and is heated from below.

Coil design for shrink fitting –

A multi turn inductor would likely be used to shrink fit a shaft to the same rotor, either around the outside of the rotor or inside the bore.

Induction annealing and coil design –

Annealing coils can be manufactured in any shaped based on the geometry of your part. For example, if you need to anneal a flat surface, you may use a face heating coil. However, if you want to anneal the outside of a cylinder, using an outside heating coil would be more efficient.

Die hardening and induction heating coil design –

Hairpin coils are typically used for die hardening since the idea is to heat a small area and then move the coil as it is energized to heat along the cutting edge of the die.

All shapes, sizes and brands coil replacement

Induction coil fabrication is one of eldec’s specialities. Whether you need to braze butt joints, shrink fit a shaft to a rotor, heat a work piece from the bottom or from multiple sides, eldec can custom manufacture induction heating coils to meet your needs. We can design from scratch or manufacture an induction coil replacement – even one made by another manufacturer.

Induction coil design and fabrication company to meet your specific application demands and requirements.

Your parts, your manufacturing environment and your employees are unique. Each presents its own set of challenges and opportunities. Our technical experience and know-how combined with powerful induction heating systems and quality, custom inductor design as well as specialized training programs will help you improve your plant’s operational efficiency and your parts’ value. Let eldec’s team demonstrate how in an inductor design and process review. Schedule consultation today.